![]() +86 189 5353 7121

+86 189 5353 7121

Automatic hot foil stamping machine

The essence of hot stamping is transfer, that is, the process of transferring the pattern on hot stamping paper to the substrate surface through the action of temperature and pressure. During hot stamping, the adhesive layer of hot stamping paper melts and forms adhesion on the surface of the substrate. At the same time, the hot paper release agent in the silicone flow and carrier film separation, carrier film on the text is transferred to the substrate. The reason why transfer printing can be carried out is that the thermal adhesion of hot melt adhesive and release agent thermal adhesion disappear, hot printing can adapt to most substrates, especially paper, plastic, wood, leather and so on.

In order to improve the added value and technological content of printed matter and enrich the product style, people pay more and more attention to post-press finishing. Nowadays, although due to the development of science and technology, cutting, post-press finishing process innovation, cold stamping, holographic positioning stamping and other new processes, but the traditional stamping (also known as hot stamping) as an important post-press finishing process, plays a unique decorative role in printed matter, and has not been ignored by other packaging, on the contrary, it is still people’s attention and favor.

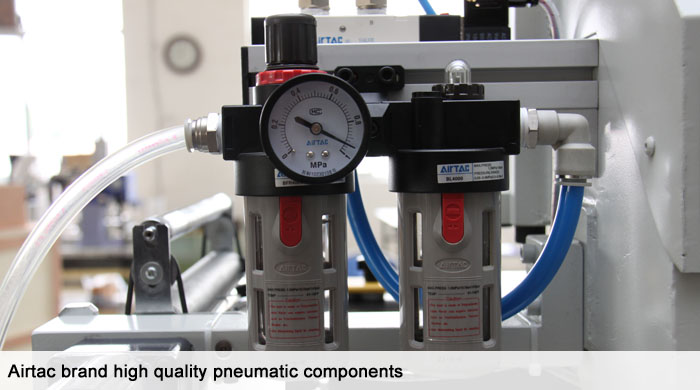

So, if you want to enrich your product style, it’s time to upgrade your bronzing machine equipment. HUAXIANG is a professional bronzing machine supplier, we have rich production experience, with different kinds of bronzing machine, safe, efficient, easy to operate, can be used for different materials, such as paper, PU, leather, plastic cement, hard rubber, PVC soft rubber, wood, bamboo products, photos, cloth products and so on. If you are looking for the perfect bronzing machine, you need look no further. HUAXIANG can help you. Feel free to contact us.