![]() +86 189 5353 7121

+86 189 5353 7121

How to adjust and use the bronzing machine?

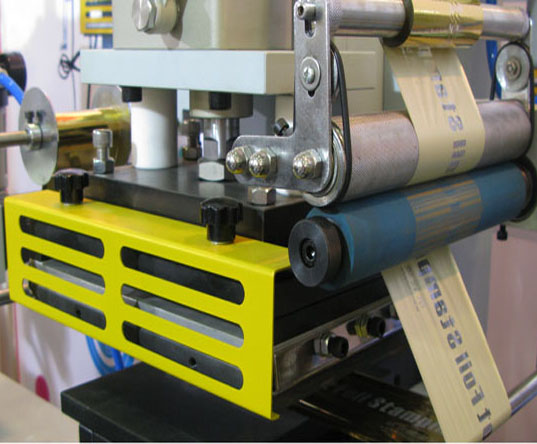

Bronzing machine is a bronzing process, is a special printing technology without ink. To put it bluntly, hot stamping refers to the whole process of hot stamping on the printed surface at a certain temperature and working pressure. Bronzing machines are machines and equipment used in the process of bronzing. Only the correct operation of machinery and equipment, in order to produce higher rights and interests in the work.

How to adjust the bronzing machine?

1. Turn on the power supply.

2. Prepare the hot stamping plate, heat it, comb the hot stamping paper, calibrate the plate, and adjust some intervals to hot stamping.

3. Batch samples can be produced and processed only after the person in charge of the unit is determined.

4. After that, start the bronzing process of cleaning the shell and surrounding waste. Because the quality, specification, model and specification of thermoelectric aluminum-platinum will endanger the quality of bronzing, so the scientific and standard use of thermoelectric aluminum-platinum is the premise of improving the quality of bronzing process.

How to use the bronzing machine?

1. The leader of the bronzing unit is responsible for supervising the safety of the technician of the bronzing machine.

2. Before the bronzing machine, the staff should keep the work clothes and labor protection shoes clean and tidy, and tie the clothes and sleeves. Without watches and accessories in your pockets, it’s easy for clutter to fall out. It is forbidden to put special tools, coins, pens, mobile phones, lighters and other items in clothes and pants pockets. It is forbidden to hang keys, BP machine and other items on the waist to prevent falling into the machine.

3. Before starting the bronzing machine, add the required grease (grease) to each drop point, lubrication point and car oil tank of the bronzing machine. Do not operate the bronzing machine without permission. Actually operate the bronzing machine.

4. Before running the bronzing machine, check whether there are sundries in each part of the shell. The data signal must be given before starting the bronzing machine to ensure the safety and smoothness around the bronzing machine.

5. Ensure that irrelevant personnel are close to the bronzing machine before operation.

6. Before each version of the bronzing machine, it is necessary to check whether there is dirt and ensure that the vertical cutting screw is tightened. The position of the push plate should be light to prevent damage to the bronzing machine. During the operation of the bronzing machine, it is forbidden to touch the fitness operating table by hand, overhaul and scrub the machine, and go beyond the rotating part. It is strictly prohibited to maintain the perfect safety device of the bronzing machine.

7. Technicians should stick to their posts according to the division of duties, always pay attention to the running state of each part of the stamping machine, stop immediately if any problem is found, and turn off the main power switch when stopping for a long time.

8. The working environment should be kept clean and smooth with smooth road surface. There is no sundries around the operating platform and bronzing machine. The required parts should be put into repair tools and spare parts.

9. Pay attention to the hot stamping machine: when the first piece of paper hot stamping, the machine will stop alarm, gradually increase (reduce) the working pressure manually, and then run again. In case of suspension, the actual operator should ensure safety.

10. No one is allowed to play, play or talk loudly around the bronzing machine when working.

11. After the work is finished, turn off the switch power of the bronzing machine to ensure that the waste paper around the bronzing machine is cleaned and there is no sundry in the machine.

12. The bronzing machine should be maintained and repaired on time.